Why we need automatic disinfection and blue light

The world has changed. Organizations are seeking healthier, more sustainable ways to work – reducing chemicals, saving water, and eliminating toxic substances. At the same time, infectious diseases and contamination risks are rising globally.

Yesterday’s disinfection methods – chemicals and ultraviolet radiation (UV) – are struggling to keep up.

The production and use of chemicals cause significant environmental damage, while handling strong disinfectants poses long-term health risks for workers. When it comes to disinfection performance, even the best chemical disinfectant is only as effective as the person applying it.

Ultraviolet radiation tubes are equally problematic: they are hazardous* to people and materials, contain mercury, and generate ozone.

Spectral Blue MWHI®: Next-generation disinfection technology

Critical industries like food production and pharmaceutical manufacturing need hygiene solutions that are safe, sustainable, effective – and fully automatic.

Spectral Blue MWHI® is a new, touch-free method for disinfecting indoor air and surfaces with antimicrobial blue light (aBL) that is 100% safe for people and materials. Using long-life LED technology, Spectral Blue devices contain no mercury and are far more sustainable than traditional solutions.

With Spectral Blue, disinfection becomes automatic and continuous. The result: the same high-quality hygiene, every day, without human error. Multiple disinfection cycles can run safely throughout the day, requiring no operator input.

Our continuous disinfection approach gradually drives microbial levels down and keeps them suppressed. Under constant blue-light exposure, microbes cannot regrow to dangerous levels – and even colonies within biofilms are effectively eliminated.

Multi-wavelength blue light reduces chemical use while maintaining or improving hygiene standards. It also replaces hazardous UVC radiation for example in biosafety cabinets with a safe and sustainable alternative.

Who is it for?

Spectral Blue is highly recommended for cleanrooms in pharmaceutical and medical device manufacturing, the food industry, and for laboratories handling pathogens. Healthcare facilities can also immensely benefit from the convenience and performance of Spectral Blue.

We invite you to read some of our customer testimonials to learn about real-life experiences from using Spectral Blue.

When to choose Spectral Blue?

If you’re looking for any of the following, Spectral Blue MWHI may be the ideal solution:

- Convenience, automation and scalability:

- You need touch-free, automatic, and continuous disinfection.

- You need a maintenance-free, long-lifetime solution.

- Safety & sustainability:

- You need a method that's harmless to your staff.

- You need to reduce toxic chemicals or UVC exposure.

- You need to remove mercury from your process (UVC tubes).

- You need a method that does not damage equipment or surfaces.

- You need a sustainable solution that generates no waste

- Efficiency:

- You need to eliminate bacteria, yeasts, molds, biofilms, multi-resistant strains, or spore-formers.

- You need a secondary mechanism to support and enhance your existing methods.

- You need a method that can penetrate clear glass, plastic or water.

Further reading:

- About the science behind Spectral Blue

- Test results with Spectral Blue MWHI blue light

- Multi-wavelength blue light technology explained

- Safety profile of Spectral Blue

- Full comparison between Spectral Blue and UVC and chemicals

- Why chemical disinfection does not always meet expectations

Hear it from our experts:

- Spectral Blue webinars: Introduction and industry-specific information

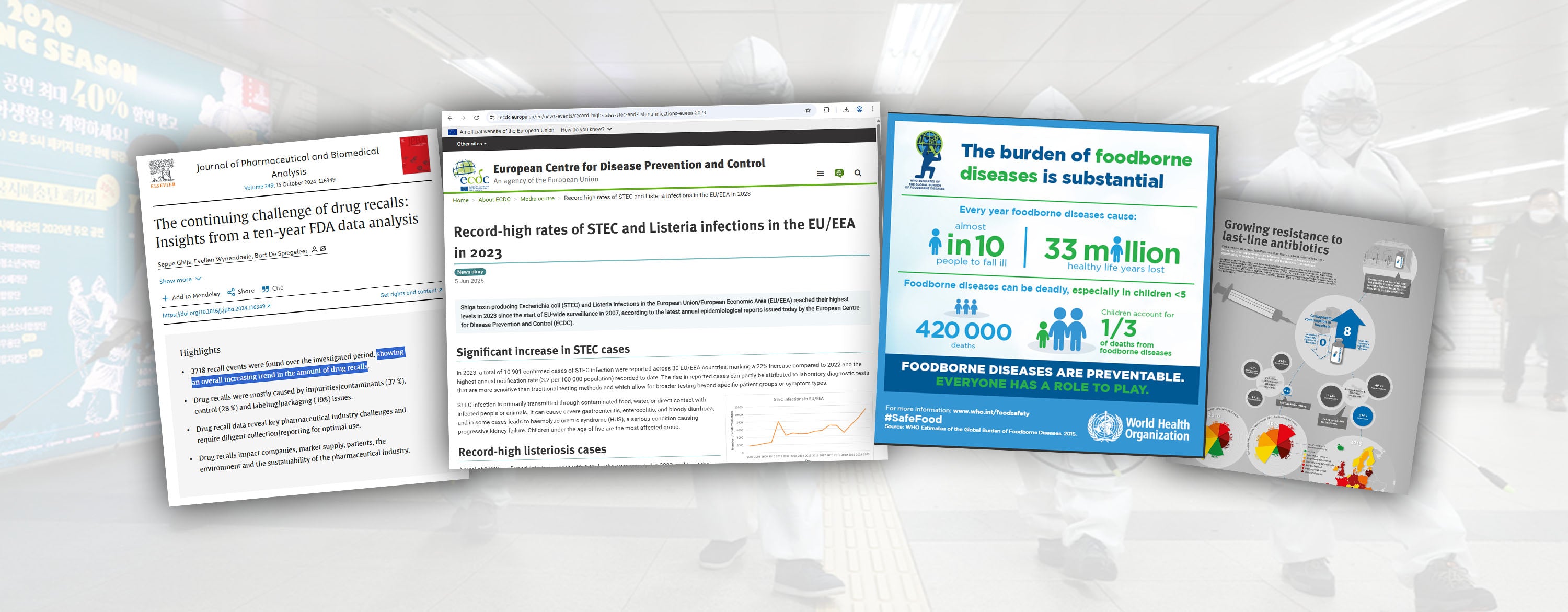

Articles and infographics referenced in top image:

- Ghijs et al, "The continuing challenge of drug recalls: Insights from a ten-year FDA data analysis". Journal of Pharmaceutical and Biomedical Analysis. Volume 249, 15 October 2024, 116349. https://doi.org/10.1016/j.jpba.2024.116349

- ECDC, 5 Jun 2025: "Record-high rates of STEC and Listeria infections in the EU/EEA in 2023". https://www.ecdc.europa.eu/en/news-events/record-high-rates-stec-and-listeria-infections-eueea-2023

- WHO, infographic: "The burden of foodborne diseases is substantial". https://iris.who.int/handle/10665/327488

- ECDC, infographic: "Antibiotic resistance: Growing resistance to last-line antibiotics". https://www.ecdc.europa.eu/en/publications-data/antibiotic-resistance-growing-resistance-last-line-antibiotics

- Photo: Workers in South Korea disinfect a subway station in Seoul to slow the SARS-CoV-2 virus’s spread. NEWSIS/ASSOCIATED PRESS

* UVC radiation is known to cause DNA damage to humans and to cause severe eye damage. UVC also degrades indoor materials, especially polymers, such as plastics, and pigments (damage to equipment, brittleness, discoloring of surface / paint).